Günter Kiefer

Master of Business Administration

Saarland University

Personal

- Interim expert with over 25 years of experience at C-level

- Strong commercial background and excellent technical expertise

- Eye for innovation and strategic opportunities

- Appreciative and solution-orientated management style

- Sustainable implementation of measures in all business areas

Expertise

- Expert for automotive and mechanical engineering

- Realisation of increased earnings in all areas

- Special requirements in challenging business situations

such as relocation of production, plant closures or insolvency - Negotiations with banks, works council committees, trade unions, customers, suppliers and investors

- M&A transactions with lead in sales strategy

- Toolmaking, pressing, welding, injection moulding, casting, machining, assembly, painting

- Steel, aluminium, plastic, hybrid materials

Professional Experience

CEO / CFO voestalpine Polynorm Grau GmbH & Co KG

Subsidiary of voestalpine AG, Linz/Austria

(today: voestalpine Automotive Components Schwäbisch Gmünd GmbH & Co. KG)

100 million € turnover, 500 employees, automotive tier 1

prototypes, pressing tools, pressed parts, components, parts made of press hardening steel

- Construction of a press shop for car body parts in 9 months (greenfield)

- Integration of two tool shops

- Restructuring and strategic realignment

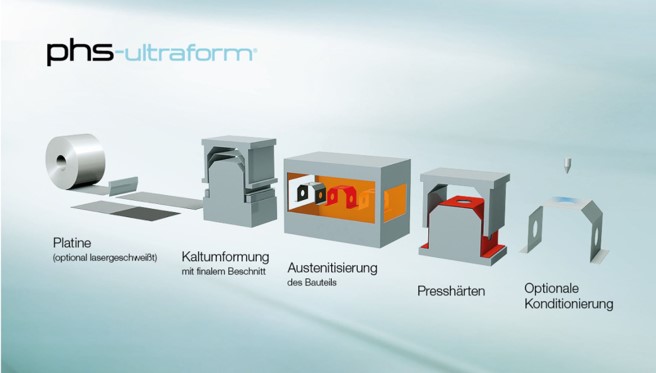

- Development of processing method and market launch of the innovation

press parts made of press hardening steel with phs-ultraform® - Business re-engineering and launch of lean management

- Awarded Supplier of the Year by VW North America

- Audi, Bentley, BMW, Mercedes-Benz, Opel, Porsche, Saab, VW

CFO der Haden Drysys, Frankfurt

Subsidiary of Haden MacLellan Holdings plc, Egham/UK

32 million € turnover, 35 employees, automotive Tier 1

Sales and project management for automotive painting systems

Projects:

- BMW Rosslyn, South Africa (paint shop and building)

- Opel Azambuja, Portugal (paint shop and building)

- Mercedes-Benz Sindelfingen (paint shop)

CFO der Michels GmbH Schweißanlagenbau, Saarbrücken

45 million € turnover, 300 employees, automotive tier 1

- Welding lines for car bodies (BIW) and cells for doors, flaps and structural assemblies

Series production of welded components for cars and buses - Establishing cost transparency

- Establishing controlling and liquidity management for multi-year projects

- Establishing claim management

- Implementation of CAD system CATIA and offline programming RobCad

- Implementation of CNC machine networking with centralized programming

- Business plan and realisation for a series production for structural assemblies

in the supplier park of an OEM with direct delivery - Audi, BMW, EvoBus, Ford, Mercedes-Benz, Opel, Saab, VW